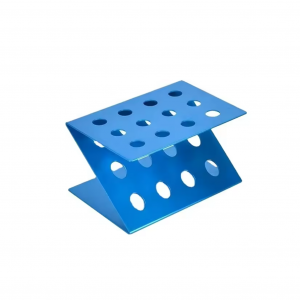

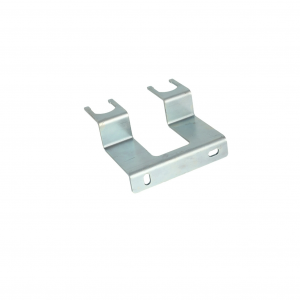

alaab-qeybiyaha habka shaabada qabow ee saxda ah

Sharaxaada

| Nooca Alaabta | alaabta la habeeyey | |||||||||||

| Hal-Stop Service | Horumarinta caaryada iyo nakhshad-gudbi muunado-wax-soo-saarka-baaritaan-kormeerka-daawaynta-baakad-bixinta. | |||||||||||

| Habka | shaabadeynta, leexinta, sawir qoto dheer, samaynta biraha xaashida, alxanka, goynta laser iwm. | |||||||||||

| Qalabka | Birta kaarboonka, birta aan fiicnayn, aluminium, naxaas, birta galvanized iwm. | |||||||||||

| Cabirka | sida ku cad sawirada macaamiisha ama muunada. | |||||||||||

| dhame | Rinjiyeynta buufinta, koronto-samaynta, galvanizing-kulul-kulul, daahan budada ah, electrophoresis, anodizing, madow, iwm. | |||||||||||

| Aagga Codsiga | Qaybaha baabuurta, qaybaha mishiinada beeraha, qaybaha mishiinada injineernimada, qaybaha injineernimada dhismaha, qalabka beerta, qaybaha mishiinada deegaanka u fiican, qaybaha markabka, qaybaha duulista, qalabka tuubooyinka, qaybaha qalabka qalabka, qaybaha alaabta lagu ciyaaro, qaybaha elektiroonigga ah, iwm. | |||||||||||

Faa'iidooyinka

1. In ka badan 10 sanoee khibradda ganacsiga dibadda.

2. Bixiadeeg hal joogsi ahlaga bilaabo naqshadeynta caaryada ilaa gaarsiinta alaabta.

3. Waqtiga gaarsiinta degdega ah, ku saabsan30-40 maalmood. In kaydka hal todobaad gudahood.

4. Maaraynta tayada adag iyo xakamaynta habka (ISOsoo saaraha iyo warshad shahaadaysan).

5. Sicir macquul ah oo badan.

6. Xirfadle, warshadeena waxay leedahayin ka badan 10sano oo taariikhda berrinkii biraha stamping biraha.

Maamulka tayada

Qalabka adag ee Vickers.

Qalabka cabbiraadda astaanta

Qalabka Spectrograph.

Saddex qalab iskudubarid.

Sawirka rarka

Habka wax soo saarka

01. Naqshadaynta caaryada

02. Habaynta caaryada

03. Goynta fiilooyinka

04. Daaweynta kulaylka caaryada

05. Shirarka caaryada

06. caaryada wax ka beddelidda

07. Deburinta

08. electroplating

09. Tijaabada alaabta

10. Xidhmada

Aasaaska shaabadaynta

Shaabadeynta (sidoo kale loo yaqaan cadaadis) waxay ku lug leedahay gelinta biraha fidsan ee gariiradda ama foomka maran mashiinka shaabadda. Saxafada, qalabka iyo dusha sare ee dhinta waxay u qaabeeyaan birta qaabka la rabo. Feerid, foorarid, foorarid, shaabad-saarid, dhejis iyo foorarid waa dhammaan farsamooyinka shaabadaynta ee loo isticmaalo qaabaynta birta.

Kahor intaan la samayn walxaha, xirfadlayaasha shaabadeynta waa inay naqshadeeyaan caaryada iyada oo loo marayo injineernimada CAD/CAM. Nashqadahani waa inay ahaadaan kuwo sax ah intii suurtagal ah si loo hubiyo nadiifinta saxda ah ee feedh kasta iyo laabashada tayada qaybta ugu fiican. Hal qalab oo 3D ah ayaa ka koobnaan kara boqolaal qaybood, markaa habka naqshadaynta badanaa waa mid adag oo waqti badan qaadata.

Marka la go'aamiyo naqshadda aaladda, soosaarayaashu waxay isticmaali karaan noocyo kala duwan oo mashiinno, shiidid, siligo goyn, iyo adeegyo kale oo wax soo saar si ay u dhammaystiraan wax soo saarkooda.

Habka naqshadaynta biraha stamping

Shaabada birta waa habsocod adag oo ay ka mid noqon karaan habab kala duwan oo biraha samaynta ah - maran, feeray, foorarsi iyo feeray, iyo kuwo kale.

Madhan: Habkani waxa uu ku lug leeyahay jarista dulucda ama qaabka sheyga. Ujeedada marxaladani waa in la yareeyo lagana fogaado burooyinka, taas oo kordhin karta kharashka qaybta iyo kordhinta wakhtiga bixinta. Tallaabadan ayaa ah in la go'aamiyo dhexroorka daloolka, joomatari/taper, kala dheeraynta cidhifka ilaa godka iyo meesha la geliyo feerka ugu horreeya.

Laabicidda: Markaad naqshadayso qaloocyada qaybo bir ah oo shaabadaysan, waxaa muhiim ah inaad ka tagto shay kugu filan oo dhinac ah - hubi inaad naqshadayso qaybta iyo bannaankeeda si ay u jiraan walxo ku filan oo aad foorarsato.

Feedh: Hawlgalkani waa marka cidhifyada qayb bir ah oo shaabadaysan la taabto si ay u fidiyaan ama u jebiyaan burooyinka; tani waxay abuurtaa cidhifyo siman meelaha kabka ee joomatari qaybta; Tani waxay sidoo kale ku kordhinaysaa xoog dheeraad ah meelaha la deggen yahay ee qaybta, waxaana loo isticmaali karaa si looga fogaado habaynta labaad sida furfurista iyo shiididda.