Stamp qaybaha birta aluminium

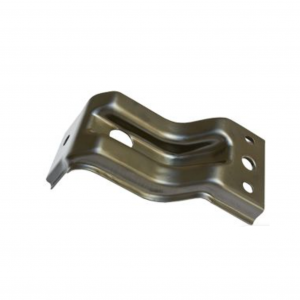

Sharaxaada

| Nooca Alaabta | alaabta la habeeyey | |||||||||||

| Hal-Stop Service | Horumarinta caaryada iyo nakhshad-gudbi muunado-wax-soo-saarka-baaritaan-kormeerka-daawaynta-baakad-bixinta. | |||||||||||

| Habka | shaabadeynta, leexinta, sawir qoto dheer, samaynta biraha xaashida, alxanka, goynta laser iwm. | |||||||||||

| Qalabka | Birta kaarboonka, birta aan fiicnayn, aluminium, naxaas, birta galvanized iwm. | |||||||||||

| Cabirka | sida ku cad sawirada macaamiisha ama muunada. | |||||||||||

| dhame | Rinjiyeynta buufinta, koronto-samaynta, galvanizing-kulul-kulul, daahan budada ah, electrophoresis, anodizing, madow, iwm. | |||||||||||

| Aagga Codsiga | Qaybaha baabuurta, qaybaha mishiinada beeraha, qaybaha mishiinada injineernimada, qaybaha injineernimada dhismaha, qalabka beerta, qaybaha mishiinada deegaanka u fiican, qaybaha markabka, qaybaha duulista, qalabka tuubooyinka, qaybaha qalabka qalabka, qaybaha alaabta lagu ciyaaro, qaybaha elektiroonigga ah, iwm. | |||||||||||

Faa'iidooyinka

1. In ka badan 10 sanoee khibradda ganacsiga dibadda.

2. Bixiadeeg hal joogsi ahlaga bilaabo naqshadeynta caaryada ilaa gaarsiinta alaabta.

3. Waqtiga gaarsiinta degdega ah, ku saabsan30-40 maalmood. In kaydka hal todobaad gudahood.

4. Maaraynta tayada adag iyo xakamaynta habka (ISOsoo saaraha iyo warshad shahaadaysan).

5. Sicir macquul ah oo badan.

6. Xirfadle, warshadeena waxay leedahayin ka badan 10sano oo taariikhda berrinkii biraha stamping biraha.

Maamulka tayada

Qalabka adag ee Vickers.

Qalabka cabbiraadda astaanta

Qalabka Spectrograph.

Saddex qalab iskudubarid.

Sawirka rarka

Habka wax soo saarka

01. Naqshadaynta caaryada

02. Habaynta caaryada

03. Goynta fiilooyinka

04. Daaweynta kulaylka caaryada

05. Shirarka caaryada

06. caaryada wax ka beddelidda

07. Deburinta

08. electroplating

09. Tijaabada alaabta

10. Xidhmada

Muuqaalka shirkadda

Sida mid ka mid ah alaab-qeybiyeyaasha Shiinaha ee hormuudka ka ah biraha shaambada leh, Ningbo Xinzhe Metal Products Co., Ltd. waxay diiradda saartaa soo saarista qaybaha baabuurta, qaybaha mishiinada beeraha, qaybaha injineernimada, qaybaha injineernimada dhismaha, qalabka hardware, qaybaha mishiinada deegaanka saaxiibtinimo, qaybaha markabka, qaybaha duulista, qalabka tuubooyinka, qalabka hardware, alaabta lagu ciyaaro, iyo qalabka elektarooniga ah, iyo waxyaabo kale.

Labada dhinacba waxay ka faa'iidaysan karaan awoodeena ah inaan si buuxda u fahanno suuqa bartilmaameedka ah oo ay bixiyaan talooyin wax ku ool ah oo ka caawin doona macaamiisheena inay helaan saami suuqa oo weyn. Waxaa naga go'an inaan siino macaamiisheena adeeg heersare ah iyo qaybo qiimo leh si aan u kasbano kalsoonidooda. Samee xiriir waara oo lala yeesho macaamiisha hadda jirta oo si firfircoon uga daba gal ganacsi cusub wadamada aan wadaagga ahayn si kor loogu qaado iskaashiga.

Habka oksidaynta

Tallaabooyinka soo socda ayaa inta badan lagu daraa habka oksaydheynta:

1. Quudinta alaabta ceeriin: Isticmaal tuubooyinka si aad alaabta ceeriin u siiso reactor si aad u ilaaliso dheelitirka saxda ah ee alaabta ceeriin ee gudaha.

2. Falcelinta: Si aad ufuliso falcelinta oksaydhka, ku dar ogsijiinta reactor-ka oo habayso cabirka falcelinta (sida heerkulka, cadaadiska, iyo wakhtiga falcelinta).

3. Kala soocida alaabta: Isticmaal qaboojiye si aad u qaboojiso alaabta la falceliyay, uga rog heerka gaaska una beddelo dareere ama qaab adag, ka dibna adeegso kala-soocida si aad u kala saarto alaabta asal ahaan ka soo jeeda qaybo kala duwan.

4. Nadiifinta: Si loo hubiyo in badeecada falcelinta ay gaarto nadiifnimada lagama maarmaanka ah, nadiifi.

5. Baakadaha: Ka dib markii alaabta la nadiifiyo, waxaa lagu baakadeeyay si waafaqsan habraacyada iyo heerarka ka hor inta aan la iibin macaamiisha ama loo dirin heerka xiga ee habaynta.

Qaar ka mid ah codsiyada gaarka ah, sida farsamaynta wafer semiconductor, habka oksaydhisku wuxuu sidoo kale ku lug leeyahay bixinta oksaydhiyeyaasha (sida biyaha, oksijiinta) iyo tamarta kulaylka substrate silikoon si loo sameeyo filim silicon dioxide (SiO2). Filimkan oksaydhku waxa uu ilaaliyaa waferka isaga oo ka hortagaya qulqulka qulqulka ee qulqulaya inta u dhaxaysa wareegyada, ka hortagga faafitaanka inta lagu jiro habka tallaalka ion, iyo u dhaqmo sida filim ka-hortagga cuncunka kaas oo ka hortagaya xoqidda khaladka ah inta lagu jiro habka xoqidda.